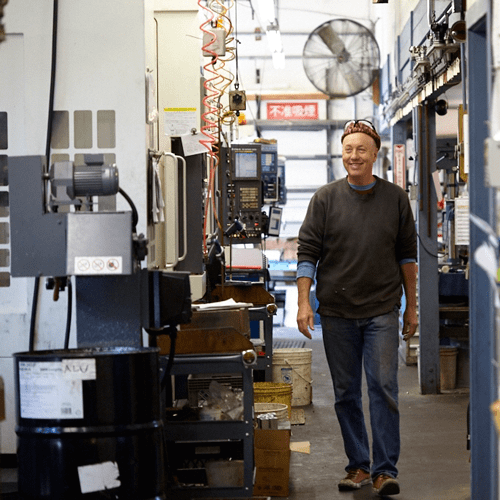

Mark Norstad

Advances in any sport are evolutionary. Successful ventures are built on and refined, while failed ones are discarded. This premise guides Mark Norstad, the founder and owner of Paragon Machine Works, when he designs and manufactures his bicycle frame building components.

Advances in any sport are evolutionary. Successful ventures are built on and refined, while failed ones are discarded. This premise guides Mark Norstad, the founder and owner of Paragon Machine Works, when he designs and manufactures his bicycle frame building components.

Mark Norstad took up riding bicycles off road in the early 1970s, before they were named mountain bikes. A desire to learn metal work led to his taking machine shop classes in high school and beyond. When he founded Paragon Machine Works in 1983, he was launching a venture that would combine his two passions, mountain biking and metal work, and lead to advances in both. From the first job he took on, making custom front dropouts, to creating the first commercially available titanium frame-building components, Mark and Paragon Machine Works have been at the forefront of mountain bike frame design and evolution.

The field of mountain bike innovation is full of brilliant people with great ideas for advancing the sport. Small builders are generally recognized as the foremost innovators of modern mountain bike geometry and style. Since most of their builds are custom, they can try new ideas quickly and easily. It’s no accident that large bicycle companies readily adopt ideas from small builders. That said, not all people have the skills or resources available to bring their ideas to fruition. Mark has the ability to work with these innovators, understand and refine their ideas, and turn their designs into solid, reliable bicycle parts. This is where Mark’s true talent and passion lies, and where he makes some of his greatest contributions to the sport of mountain biking. As Mark works through refinements and testing, a design evolves until it is ready to be incorporated into a bicycle frame. Mark is extraordinarily generous with his knowledge, always willing to help builders solve design issues and approach challenges from new angles.

A shining example of this is Mark’s contribution to the development and refinement of titanium bicycle frames, in collaboration with the pioneers of the field. Without Mark’s understanding of titanium’s mechanical properties, his exceptional machining skills and his ability to create functional parts from a notoriously difficult metal, titanium bicycle frames would not be as highly evolved as they are today. Paragon Machine Works has earned a reputation for creating aesthetically beautiful, high quality bicycle framebuilding components, including the world’s largest selection in titanium.

A shining example of this is Mark’s contribution to the development and refinement of titanium bicycle frames, in collaboration with the pioneers of the field. Without Mark’s understanding of titanium’s mechanical properties, his exceptional machining skills and his ability to create functional parts from a notoriously difficult metal, titanium bicycle frames would not be as highly evolved as they are today. Paragon Machine Works has earned a reputation for creating aesthetically beautiful, high quality bicycle framebuilding components, including the world’s largest selection in titanium.